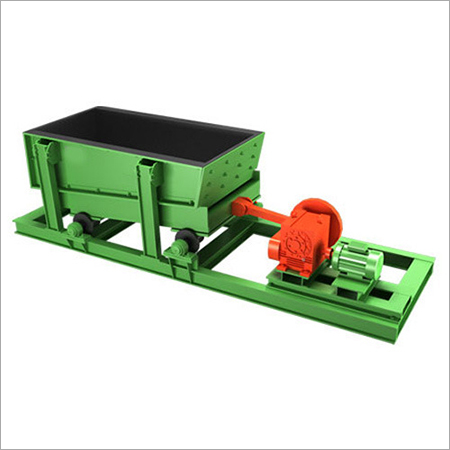

Reciprocating Feeder

Reciprocating Feeder Specification

- Lifting Speed

- Controlled via Motor Drive

- Control System

- Automatic / Manual

- Equipment Type

- Reciprocating Feeder

- Motor Type

- Electric Motor

- Rotation Type

- Linear reciprocating

- Belt Type

- Not Applicable (Provided with reciprocating tray)

- Features

- Suitable for bulk material handling

- Usage

- Industrial

- Condition

- New

- Lifting Capacity

- Up to 150 tons per hour

- Max. Lifting Load

- As per capacity

- Max. Lifting Height

- Adjustable

- Power Source

- Electric

- Power Consumption

- 2-7 kW

- Voltage

- 220-440 V

- Length of Belt

- Customized

- Feature

- Smooth Feeding, High Efficiency

- Attributes

- Heavy Duty Construction

- Installation Type

- Fixed

- Operational mode

- Continuous / Intermittent

- Drive Type

- Electric Motor Driven

- Maintenance

- Easy to maintain, minimal lubrication required

- Application

- Used for feeding bulk materials to crushers, screens, and conveyors

- Tray Width

- As per requirement

- Ambient Temperature

- -10°C to +50°C

- Finish

- Painted/Coated for corrosion resistance

- Feeding Tray Material

- Mild Steel / Stainless Steel

- Noise Level

- Low

Reciprocating Feeder Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Reciprocating Feeder

Fostered with year of industry experience and market understanding, we are making and exporting an exclusive range of Reciprocating Feeder. The offered feeder is used in various applications such as dosing, batching, mixing and etc. Manufactured by using finest quality raw materials procured from trusted vendors in the market, it is available in different specifications. It is widely demanded in market for its sturdy construction and best performance. Our clients can avail this Reciprocating Feeder at economical rate from us.

Features:

- Reliable performance

- Abrasion resistant

- Long service life

- Feeding amount can be conveniently adjusted at any time.

- Simple structure and reliable performance.

- Matching power and operating cost are both low.

- Designed with no quick-wearing parts makes equipment maintenance quite convenient.

- Occupies little space and requires just 1/5 the investment of medium plate mill.

Star Trace Reciprocating Feeder is a kind of machine that makes use of the linkage drag down dip 5 floor do straight reciprocating motion in a roll. It leads to the material ,such as coal or other abrasive small, loose granular with little sticky, powdery materials ,move from the feeding equipment into another feeding equipment evenly. The position of the crank can be regulated so as to achieve adjustment of feeding capacity.

Working Principle:

Star Trace Reciprocating Feeder started automatically dragging the bottom whose inclined angle is 5 degree to make a linear and reciprocal movement on the idlers through flexible coupling, reducer, crank connecting rod, then coal drop continously uniform on the conveying equipment or in other screening equipment.This machine can be designed as reciprocal feeder with hopper and without hopper according to request depending on order. Besides it is used for coal feeding, also used for other small polishing and viscosity scattered materials.

Structure features:

It is composed of the main frame, soleplate (coal feeding trough), transmission platform, funnel, paddle door and idlers. After the motor starting work, the soleplate with a tilt angle of 5 is dragged to reciprocate in a linear motion path on the idlers via flexible coupling and reducer,and discharging coal to other equipments.

Application:

- It is mainly used for feeding various non-sticky materials

- Mining

- Construction

- Quarry

- Abrasive materials

Specification

|

Brand |

Shakti |

|

Power Type |

Electric |

|

Material |

Carbon steel or stainless steel |

|

Application |

Coal,Mining |

|

Widths |

800 mm to 2500 mm |

|

Lengths |

1600 mm to 3200 mm |

|

Capacity (TPH) |

250 to 1400 |

Heavy Duty and Efficient Design

With rugged construction and quality materials, this reciprocating feeder ensures long-lasting performance under demanding industrial conditions. Its versatility allows it to handle large material loads and operate seamlessly, whether in continuous or intermittent modes, optimizing your bulk handling processes.

Customizable for Your Application

The feeders tray width, belt length, lifting height, and operational mode can all be tailored to your specific requirements. Choose from painted or coated finishes for durability, and rely on low power consumption to keep your operations cost-efficient.

Advanced Control and Ease of Maintenance

Featuring automatic or manual controls and an adjustable, controlled lifting speed, this equipment simplifies operation and integration into existing material handling systems. Minimal lubrication needs and easy access for upkeep further reduce downtime and maintenance costs.

FAQs of Reciprocating Feeder:

Q: How does the reciprocating feeder work in industrial applications?

A: The reciprocating feeder utilizes an electric-motor-driven linear movement to transfer bulk materials from its tray onto crushers, screens, or conveyors. This mechanism ensures consistent, controlled, and efficient feeding.Q: What materials can the feeding tray be made from and why?

A: The feeding tray is available in either mild steel or stainless steel. Stainless steel offers superior resistance to corrosion, making it ideal for handling abrasive or corrosive materials, while mild steel provides robust performance for standard bulk applications.Q: When should I choose continuous versus intermittent operational mode?

A: Continuous mode is recommended for operations requiring steady material flow, such as in automated production lines. Intermittent mode suits processes where feeding needs to be paused or precisely controlled at intervals, providing flexibility for different industrial setups.Q: Where is this reciprocating feeder typically installed?

A: The feeder is fixed in position within industrial plants, placed at the start of bulk material handling systemscommonly upstream of crushers, screens, or conveyorsto optimize the feeding process efficiently.Q: What is the installation process for this equipment?

A: Installation involves securely mounting the feeder at your desired location, connecting the electric motor to the specified voltage, and calibrating the control system (manual or automatic) as per operational requirements. Professional installation ensures peak performance and longevity.Q: How does easy maintenance benefit my operation?

A: The feeder is engineered for easy maintenance, requiring only minimal lubrication and regular visual checks. This design reduces downtime, lowers maintenance costs, and ensures reliable operation even in heavy-duty environments.Q: What are the main benefits of using this reciprocating feeder in a bulk material handling system?

A: Key benefits include high feeding efficiency, robust construction, low noise levels, easy integration, and significantly improved control over material flow, all contributing to streamlined operations and enhanced productivity in industrial settings.

Price 175000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

SHAKTI ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |