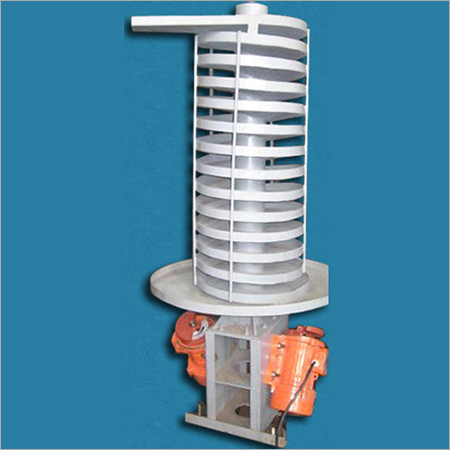

Vibrating Spiral Elevators

Vibrating Spiral Elevators Specification

- Car Dimension

- N/A (no car, spiral tube design)

- Usage

- Material Elevation, Cooling, Drying, and Conveying

- Type

- Vertical Spiral Elevator

- Load Capacity

- Up to 500 Kg/batch

- Inclination

- Vertical (up to 90)

- Noise Level

- 80 dB

- Hoist Way Size

- Customized as per design

- Voltage

- 220-415 V

- Material

- Stainless Steel (AISI 304/316)

- Drive Type

- Electromechanical vibrating motor

- Power Supply

- 3-Phase AC

- Speed

- 0.11 m/s

- Max. Lifting Height

- Up to 6 meters

- Max. Lifting Weight

- 500 Kg

- Mechanism Type

- Vibratory Spiral Conveyor

- Working Temperature

- -10C to +60C

- Control Device

- VFD panel (Variable Frequency Drive)

- Safety Device

- Overload & over-temperature protection

- Capacity

- Up to 5 TPH (tons per hour)

- Feeding Method

- Top/Bottom Entry Possible

- Application Industries

- Food, Chemical, Pharmaceutical, Mining, Plastic, Metallurgy

- Maintenance

- Minimal, easy-access design

- Spiral Diameter

- 300 to 1200 mm

- Installation Type

- Floor Mounted

- Vibration Amplitude

- Adjustable via control panel

- Trough Width

- 100 to 600 mm

- Ingress Protection

- IP54 or higher (vibrator motor)

- Surface Finish

- Smooth polished or shot-blasted

- Optional Features

- Heating/cooling jackets, Sensors, Dust covers

- Discharge Point

- Single or Multiple possible

Vibrating Spiral Elevators Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Vibrating Spiral Elevators

Being a quality conscious unit, we are highly indulged in fabricating and offering an exclusive range of Vibrating Spiral Elevators. These elevators are used in various industries such as food, feed, chemical and pharmaceutical. Manufactured by using tested quality materials and advance techniques, the offered elevators are specially designed for vertical elevation and provide silent operation. These elevators are strictly tested on various parameters to ensure its flawlessness. We offer these Vibrating Spiral Elevators at suitable price to the clients.

Our organization is counted among the leaders in manufacturing and supplying Vibrating Spiral Elevators. Provided spiral elevators are use in various industries such as food, feed, chemical-technical and pharmaceutical industry. These spiral elevators are developed utilizing best quality material and advance technology in accordance with set guidelines. Moreover, these spiral elevators are highly accredited for their reliability among our patrons.

Features:

- Low maintenance

- Optimum strength

- Best performance

- Precisely engineered

The functions carried out by these Elevators are:

-

To carry material vertically within shortest available space, wet material fed at bottom need to be dry when it reaches delivery point (Its usage saves space as in many processes, big area is occupied for drying of material/re-cycling of material)

-

In pulverizing process, certain fineness of powder is required. Here, users can re-feed bigger particles, after sieving to pulverize, automatically, thus increasing efficiency of entire operations

Specification

|

Dimension |

700 - 1800 mm |

|

Power |

1.5 - 3 kw |

|

Brand |

Shakti |

Versatile Application Across Industries

Vibrating Spiral Elevators serve a broad spectrum of industries, excelling in material elevation, conveying, drying, and cooling tasks. Their customizable size and robust design make them ideal for handling a wide range of materials, from fine powders to bulk solids, securely and efficiently. This adaptability opens new possibilities for production lines aiming for consistent and hygienic processing conditions.

Efficient Operation with Minimal Maintenance

Engineered for easy access and simplified upkeep, these elevators feature smooth-polished or shot-blasted surfaces that minimize material build-up and make cleaning straightforward. The floor-mounted design ensures stable operation, while advanced safety features and controls reduce downtime and allow operators to adjust vibration amplitude effortlessly for optimal throughput.

Advanced Control and Safety Features

Equipped with VFD panels for adjustability, overload and over-temperature protection, and IP54 or higher ingress protection for motors, these spiral elevators prioritize dependable performance and operational safety. Optional heating/cooling jackets, dust covers, and sensors further enhance process integration, ensuring materials are handled according to stringent industry requirements.

FAQs of Vibrating Spiral Elevators:

Q: How does the Vibrating Spiral Elevator improve material handling efficiency in a production setting?

A: The Vibrating Spiral Elevator automates vertical movement and processing of materials, enabling efficient elevation, cooling, drying, or conveying. Adjustable vibration parameters and controlled speed assure precise and consistent flow, reducing manual intervention and ensuring streamlined operations that enhance overall productivity.Q: What materials and industries are suitable for using these elevators?

A: These elevators are manufactured from stainless steel (AISI 304/316) or sheet metals, making them ideal for processing sensitive or abrasive materials. Industries such as food, chemical, pharmaceutical, mining, plastic, and metallurgy benefit from their hygiene, durability, and tailored configurations.Q: When should I consider adding optional features like heating or cooling jackets?

A: Optional heating or cooling jackets are recommended when temperature control is essential during elevation, such as in food processing (maintaining product quality), chemical industries (preventing reactions), or plastics processing (achieving specific properties). These integrations help customize the elevator for specialized operational needs.Q: Where can these elevators be installed, and are they customizable to fit my facility?

A: These elevators are designed for floor-mounted installation and can be customized to match facility layouts. The spiral diameter, trough width, lifting height, and hoist way size are adaptable to meet unique site requirements, ensuring seamless integration with existing equipment and spaces.Q: What process controls are included for managing elevator speed and vibration amplitude?

A: A Variable Frequency Drive (VFD) panel allows operators to adjust the speed from 0.1 to 1 m/s and modulate vibration amplitude, ensuring optimal handling for a variety of materials. These control features provide flexibility to accommodate changing production demands.Q: How does the elevator ensure operator safety and equipment reliability?

A: Safety features such as overload and over-temperature protection, IP54 or higher ingress protection for vibrator motors, and noise levels 80 dB foster a safe working environment. These measures safeguard both personnel and equipment, supporting sustained, trouble-free operation.Q: What are the main benefits of using a vibrating spiral elevator compared to traditional conveyors?

A: Vibrating spiral elevators offer vertical transport, integrated processing (cooling, drying), minimal maintenance, easy cleaning, space-saving installation, and customizable discharge points. Their advanced controls and robust construction surpass traditional conveyors in versatility, efficiency, and long-term reliability.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spiral Elevators Category

Spiral Elevator

Minimum Order Quantity : 10 Pieces

Drive Type : Other, Electric Motor Driven

Material : other Sheet, Stainless Steel / Carbon Steel

Voltage : 220V/380V

Max. Lifting Height : 10 meters

|

SHAKTI ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |