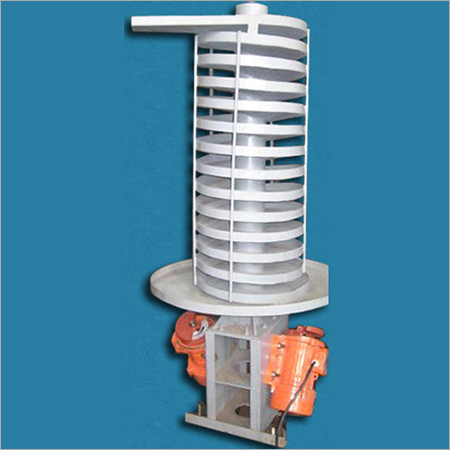

Spiral Elevator

Spiral Elevator Specification

- Step Width

- 300600 mm

- Inclination

- Vertical / Spiral

- Load Capacity

- Customizable as per requirement

- Usage

- Powder, Granules, Bulk Material Handling

- Noise Level

- 80 dB

- Voltage

- 220V/380V

- Type

- Vertical Conveyor / Spiral Elevator

- Material

- Stainless Steel / Carbon Steel

- Drive Type

- Electric Motor Driven

- Power Supply

- Three Phase AC

- Speed

- Up to 3 m/min

- Max. Lifting Height

- 10 meters

- Max. Lifting Weight

- Up to 1500 kg

- Mechanism Type

- Continuous Spiral Conveyor

- Working Temperature

- -10C to +60C

- Control Device

- PLC Control Panel

- Safety Device

- Overload Protection, Emergency Stop

- Capacity

- 502000 kg/h

- Vibration Motor Type

- Heavy Duty, High Efficiency

- Finish Type

- Polished/Industrial

- Installation

- On-site Installation Support

- Feeding/Discharging Height

- Adjustable as per site need

- Diameter of Spiral

- 6001200 mm

- Maintenance

- Low Maintenance Design

- Mounting

- Floor Mounted or Customized

- Application Area

- Food, Chemical, Pharmaceutical, Packaging Industries

- Transport Direction

- Upward or Downward

- Number of Layers

- Single or Multiple

Spiral Elevator Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

About Spiral Elevator

We have been counted among the well known companies, which manufacture and offer high quality range of Spiral Elevator. Manufactured under the direction of senior professionals using finest quality raw material and advanced techniques, this elevator is used to wide range of operations like conveying products with wet, dry, frozen greasy and etc. This elevator is checked on various standard quality parameters to ensure its defect free range is delivered to the clients. Our clients can avail this Spiral Elevator at competitive price from us.

Our clients can benefit from us an unlimited scope of Spiral Elevator which are exceptionally vigorous in configuration. A portion of the quiet peculiarities of these Elevator are its low support, high strength. Dust security, simple moving and different others. Our items find their wide application in keeping up different plastic beds, grains items, sustenance transforming, and fine materials. We are putting forth these Elevator at most complete rate.

Features:

- Easy to use

- Best performance

- Durable

Other Details:

- Shakti engineers have now started manufacturing SPIRAL ELEVATORS which so far are not so popular in India

- The main advantage of spiral Elevators is that it can convey powders, small parts, vertically without occupying valuable space. In a way it helps you to expand vertically

Many functions are carried out by these Elevators:

- To carry the material vertically within shortest available space

- Wet material fed at the bottom can be dry when it reaches the delivery point

- In many a process, big area is occupies for drying the material. Re Cycling of Material

- In pulverizing process, at the output certain fineness of powder is necessary

- You can re-feed the bigger particles, after sieving to the pulverize, automatically

- Thereby increasing the efficiency of the entire operation

- This is just one example of the benefits of a Spiral Elevator

- Please contact us for these items along with your problems

- We hope we will definitely find a solution

- Our other products are Vibratory Sieves, Tables Feeders, Bowl Feeders, Rotary Vibrators, Geared Motors etc.

Specifications:

- Size: 25 G, 26 G, 27 G, 28 G, 29 G, 30 G

- Moq: 500 pcs.

Specification

| Capacity(kg) | Customized |

| Material | carbon steel or stainless steel |

| Brand | Shakti |

| Structure | Chain Conveyor |

| Type | Vertical Conveyor |

| Type | Outside Diameter | Center line Diameter | Slat Width | Frame Width |

| 1700-400-HC | 7" - 3" (2200) | 5" - 7" (1700) | 16" (400) | 1" - 7" (480) |

| 1700-600-HC | 7" - 11" (2400) | 5" - 7" (1700) | 24" (600) | 2" - 3" (680) |

Efficient Material Handling

The Spiral Elevator streamlines vertical transportation of powders, granules, and bulk materials with customizable lifting heights up to 10 meters and load capacities tailored to your requirements. Its efficient electric motor and heavy-duty vibration drive ensure consistent throughput, reaching speeds of up to 3 meters per minute while maintaining low operational noise.

Built for Versatility and Safety

Designed for diverse application areas such as food, chemical, pharmaceutical, and packaging industries, this elevator offers both upward and downward transport. Overload protection, emergency stop functions, and a polished or industrial finish enhance both operator safety and hygienic operation. Floor-mounted or customized installations adapt seamlessly to your facility.

Low Maintenance and Easy Operation

The spiral elevator is engineered for reliability, featuring a low-maintenance design and robust materials (stainless steel or carbon steel). The integrated PLC control panel provides straightforward operation and precise adjustments, while on-site installation support ensures smooth setup and commissioning.

FAQs of Spiral Elevator:

Q: How does the Spiral Elevator facilitate material transport in industrial environments?

A: The Spiral Elevator continuously moves powders, granules, or bulk materials vertically by means of a spiral conveyor, propelled by a heavy-duty vibration motor. This design enables upward or downward transport, making it ideal for integrating with other processing equipment in food, chemical, pharmaceutical, and packaging plants.Q: What are the customization options available for the Spiral Elevator?

A: Customization options include spiral diameter (6001200 mm), number of layers (single or multiple), loading and discharging heights, finish type (polished or industrial), inclination, step width, loading capacity, and material choice (stainless steel or carbon steel), ensuring an exact match for your facilitys requirements.Q: When should I consider using a spiral elevator instead of traditional conveyors?

A: A spiral elevator is recommended when space efficiency, vertical material movement, or gentle product handling is needed. Its ability to handle various capacities (502000 kg/h) and heights (up to 10 meters) makes it suitable for process integration and vertical conveying where floor space is limited or multiple levels are involved.Q: Where can the Spiral Elevator be installed within my facility?

A: Thanks to its floor-mounted or customizable installation design, the spiral elevator can be set up almost anywhere within your facility, provided there is suitable vertical clearance. Our team provides on-site installation support to ensure proper placement and seamless integration into existing workflows.Q: What process controls and safety features are included with this elevator system?

A: The Spiral Elevator comes equipped with a PLC control panel for precise process adjustments and monitoring. Safety is enhanced through integrated overload protection and an emergency stop system, providing peace of mind for operators and compliance with workplace safety standards.Q: How is the maintenance requirement minimized for this elevator?

A: Its robust build, quality materials (stainless/carbon steel), and heavy-duty motor design contribute to long service intervals and reduced downtime. The continuous spiral mechanism and polished finish facilitate easy cleaning, making this system exceptionally low maintenance for demanding industrial operations.Q: What are the main advantages of using a Spiral Elevator for bulk material handling?

A: Key benefits include high efficiency, space savings due to vertical design, adjustable speed and lifting capacity, noise levels 80 dB, and versatile handling of a wide range of materials and quantities. Its adaptable design, safety features, and low operational requirements make it a reliable solution for various industries.

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spiral Elevators Category

Vibrating Spiral Elevators

Minimum Order Quantity : 1 Piece

Hoist Way Size : Customized as per design

Material : other Sheet, Stainless Steel (AISI 304/316)

Speed : 0.11 m/s

Control Device : Other, VFD panel (Variable Frequency Drive)

Working Temperature : 10C to +60C

|

SHAKTI ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |